Modern manufacturers depend on precision, speed, and stability. Upgrading to advanced Bridge/Gantry mills can bring all this and more. When your older machines show signs of wear, struggle with accuracy, or take too long on parts, it may be time to rethink your equipment strategy.

Here are five concrete signs that your productivity may improve with a high-performance Bridge/Gantry mill.

1. Accuracy Is Slipping Beyond Acceptable Limits

When prototype parts or final components show dimensional errors, something is wrong. Your current Bridge/Gantry mill may no longer meet micron-level tolerances.

- Worn guide rails cause drift and backlash.

- Vibration from underpowered spindles leads to chatter.

- WORN TURCITE

A high-performance Bridge/Gantry mill maintains rigidity with a heavy-duty frame. Precision rails, hardened ballscrews, and thermal control systems all help preserve accuracy across long runs.

2. Your Throughput Is Suffering from Complex Parts

If you’re running jobs on one machine, then moving parts to another for additional mill work costs time and creates setup errors.

Older Bridge/Gantry mills may require multiple setups for the same part, which slows workflow.

Modern Bridge/Gantry mills combine large workspaces with multi-axis capability. They allow heavy, complex parts to be machined in one setup—reducing cycle times and indexing errors.

3. Material Choices Are Becoming More Exotic

If you’re machining hardened steel, titanium, or Inconel, your older Bridge/Gantry mill may stall or overheat.

Signs include:

- Frequent tool wear or breakage

- Slower feed rates to avoid thermal drift

- POOR FINISHES

High-performance Bridge/Gantry mills come with high-torque spindles and advanced cooling. They handle exotic alloys without sacrificing speed, meaning fewer rejects and faster material removal.

4. Maintenance Downtime Is Eating Your Schedule

Frequent or unexpected breakdowns can throw your entire production schedule off.

Older Bridge/Gantry mills often require repeated repairs to linear guides, drive belts, or control boards. That translates into more downtime and higher costs.

Upgrading to a modern Bridge/Gantry mill delivers more durable components, advanced controls, and stronger service plans—helping your operation run longer between maintenance cycles.

5. You’re Ready to Move to Automation and Digital Workflows

Industry 4.0 demands automation, in-process probing, and remote monitoring. But an older Bridge/Gantry mill may not support these features.

Next-level Bridge/Gantry mills include:

- Robot-tended loading systems

- In-process inspection and probing

- Remote CNC diagnostics

These help reduce human error, increase uptime, and integrate smoothly with digital shop-floor systems.

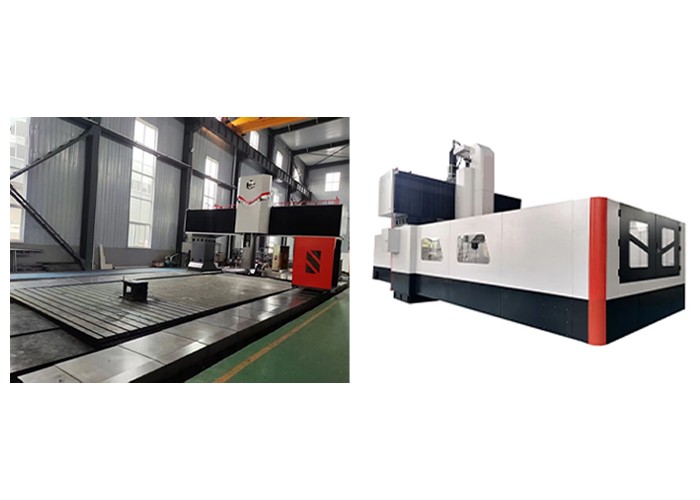

Why Bridge/Gantry Mills Make Sense?

Bigger Work Envelope

Bridge/Gantry mills offer a larger work envelope compared to standard machining centers. This means you can handle oversized parts and heavier fixtures with confidence.

Rigidity and Damping

The bridge and gantry construction resist deflection, delivering sharper cuts and better surface finishes, even on large aerospace or mold components.

Application-Driven Choice

It’s important to remember that the application defines whether a Bridge or Gantry configuration is best. Bridge setups may be preferred for certain heavy-duty, high-precision aerospace or mold work, while Gantry designs may be more suitable for large, long-span components.

Service Ecosystem

Precision-Tec provides retrofit, rebuild, CNC control upgrades, spindle replacements, and realignment services for both Bridge and Gantry mills. This extends machine life and ROI.

Industries Benefiting Most from Upgraded Bridge/Gantry Mills

Clients across these sectors find Bridge/Gantry mills essential:

- Aerospace: Engine parts, landing gear, structural sub-assemblies

- Oil & Gas: Large valve bodies, pump housings, flanges

- Heavy Machinery: Construction frames, railroad components

- Tool & Die: Large molds with deep cavities

Each application requires tight tolerances and consistent cycle times—delivered effectively by modern Bridge/Gantry mills.

Conclusion

Upgrading to a high-performance Bridge/Gantry mill can transform production efficiency. You’ll see reduced setups, tighter tolerances, less downtime, and smoother automation integration.

The key takeaway: the right application defines whether Bridge or Gantry is best for your operation. Both deliver large work envelopes, strength, and stability, ensuring you’re prepared for modern manufacturing challenges.

Precision-Technologies offers full support for Bridge/Gantry mills—from CNC control upgrades and spindle rebuilds to full machining center retrofits. When your parts demand the highest precision, our expertise ensures your equipment performs at its best. For more, contact us today.

Frequently Asked Questions

- What’s the difference between a Bridge and a Gantry mill?

Both Bridge and Gantry mills are designed for large and complex parts. Bridge configurations generally offer higher rigidity and vibration damping for heavy-duty precision work, while Gantry setups provide flexibility for very large components or wide-span parts. The choice ultimately depends on the application requirements.

- When should I consider upgrading instead of repairing my current mill?

If you’re experiencing recurring accuracy issues, excessive downtime, or limitations with materials and automation, it may be more cost-effective to upgrade to a high-performance Bridge/Gantry mill rather than continuing to invest in an older machine.

- Can Bridge/Gantry mills handle titanium and other exotic alloys?

Yes. Modern Bridge/Gantry mills are built with high-torque spindles, advanced cooling, and rigid construction. These allow efficient machining of titanium, Inconel, hardened steels, and other exotic materials—without compromising tool life or speed.

- How does automation work with Bridge/Gantry mills?

Advanced Bridge/Gantry mills support robotic loading, in-process probing, automatic tool changers, and remote CNC monitoring. These features reduce human error, increase uptime, and enable smooth integration with digital manufacturing workflows.

- Will upgrading to a Bridge/Gantry mill affect my workflow?

Absolutely—in a positive way. You’ll experience fewer setups, faster cycle times, higher repeatability, and better readiness for automation. Whether Bridge or Gantry is right for you depends on the application, but both deliver significant gains in productivity.